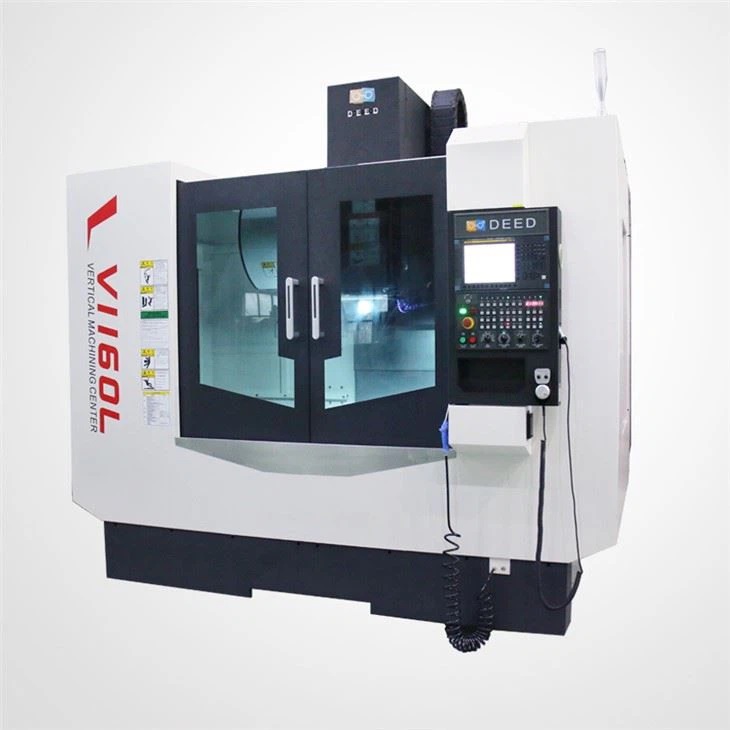

| Model: | V1160L |

|---|---|

| Category: | CNC-Machines |

Product Information

The structure of the tool of CNC vertical machining machine V1160L has been greatly improved. The vibration frequency of the machine tool is far higher than the inherent process system. Therefore, the workpiece is basically in a "vibration free" stable state during high-speed cutting, and the influence of cutting force and cutting heat is small, so it is easier to obtain parts with higher machining accuracy. In addition, due to the effective control of chip nodule, surface residual stress and other defects in the higher cutting speed range, the machine can obtain the quality of the machined surface during high-speed cutting, effectively reducing the subsequent processing procedures.

Features

Because high-speed cutting has small cutting force, small cutting deformation and tool is not easy to wear, the CNC vertical machining machine V1160L can be used to process some materials that are difficult to machine, such as aluminum alloy, magnesium alloy, nickel alloy and titanium alloy, which are widely used in aerospace industry. Generally speaking, these materials have the characteristics of high strength, high hardness, high abrasion resistance and impact resistance. High speed cutting can effectively reduce tool wear, prolong tool life, improve production efficiency, and obtain higher surface quality.

Specification

TRAVEL

X-axis travel 1100mm

Y-axis travel 610mm

Z-axis travel 610mm

Spindle nose to table surface 150~760 mm

SPINDLE

Drive type Belt drive/Direct drive

Spindle taper BT40

Max. Speed 8000 rpm / 10000 rpm

Spindle Power 11/18.5 kW

Spindle Torque 52.5/118 Nm

TABLE

Size 1200x600mm

T-Slot (size * quantity * space) 18x5x100mm

Max load 1000kgs

FEED

Max.cutting speed 1-12000 mm/min

Rapid traverse 36/36/24 m/min

ACCURACY

Positioning(half-closed loop) 0.008mm

Repeatability(half-closed loop) 0.005mm

ATC

Type Disc type ATC 24T

Maximum tool size(full/unfull/length) Φ78/Φ150/ 300 mm

Maximum tool weight 8kg

OTHERS

Air Pressure 0.65Mpa

Power Capacity 25kVA

Machine Weight 7000kgs

Machine Floor Space (L *W *H) 2900x2800x3200mm

Standard

Whole machine cover

Belt type spindle BT40-8000rpm

Spindle taper air blow

Spindle air curtain dust-free

Spindle ring spray

Flexible cover

Tri-color alarm light

Auto lubrication system

Air gun

Disk type ATC BT40-24T

Heat exchange for electrical cabinet

Manual pulse generator

Working lamp

4-axis preparation

Communication interface

Workpiece water cooling

Workpiece air cooling

Option

CTS 20bar/30bar

Chain type conveyor and cart

Electric cabinet air conditioner

Flush device

Spindle temperature control system

Water gun

Siemens/Mitsubishi controller

Industries That Most Commonly Use Worm Thread Grinding Machines Worm thread g...

Product Description Forming machine for construction and large metal structures...

DESCRIPTION Table size 2200 x 1000 mm Byu3Fq8Cur Longitudinal travel 2050 mm...